Topic of efficiency and fuel efficiency

Efficiency (efficiency factor) is the degree of efficiency of using fuel energy in the engine, the higher it is, the more thermal energy from the combination of fuel is converted in the engine into mechanical energy of rotation of the main shaft. The less fuel the engine consumes per unit of output power.

ARTICLE #1

ENGINE EFFICIENCY - TUNING OF GLOBAL IDEAS,

Are there any prospects for improving engines?

Modern internal combustion engines have reached today's efficiency and fuel efficiency values many decades ago - with the advent of direct injection and turbocharging systems for air entering the cylinders. Therefore, today, global corporations - manufacturers of engines for cars and other equipment spend a lot of money and many years of effort to increase the efficiency by only 2 - 3% due to high costs and significant complication of engine design. Efforts and costs are completely incomparable with the result. The result of all this - as in the famous proverb - "the mountain gave birth to a mouse."

By the way, that is why in all major countries there is a whole industry of “engine tuning”, i.e. a huge number of small firms, semi-handicraft workshops and individual specialists who undertake to somehow bring the standard engines of mass brands of cars to higher levels of power, traction, etc. Ie. subject the engine to fine-tuning, refinement, forcing, etc. tricks that are popularly defined as engine tuning.

But all these events and technical actions on motors are very standard in nature, and all these tuning ideas are at least half a hundred years old. Let me remind you that turbocharging of the air entering the engine was successfully used back in the 20s of the last century, and the first US patent for such a device was received by Swiss engineer Alfred Buchi already in 1905 ... And systems of direct fuel injection into cylinders were massively used in piston engines military aviation already in the initial period of the 2nd World War. Those. all modern "advanced" technical systems for the struggle to increase the efficiency and fuel efficiency of engines are already over a hundred years old, or even more. With all these tricks, the overall efficiency of the best gasoline engines (with spark ignition) does not exceed 25-30%, and the efficiency of the best diesel engines in their most economical large-sized versions (which have many complex additional devices) cannot exceed 40 for many decades. -45%. For small diesel engines, the efficiency is 10 percent lower.

In this article, we will try to briefly and in a popular language state the main tasks and determine the theoretical possibilities of creating an internal combustion engine with a confident efficiency above 50%.

* * * So - the efficiency of the engine, judging by the textbooks for technical universities, consists of two values: thermodynamic efficiency and mechanical efficiency .

The first value indicates how much of the heat generated in the engine is converted into useful work, and how much is wasted into the surrounding space. The mechanical efficiency indicates how much of the active operation of the engine is uselessly spent on overcoming various mechanical resistances and driving additional equipment in the engine itself.

But for some reason, in all textbooks, the concept of “fuel efficiency” is not introduced into the concept of overall efficiency. That is, a value that will show how much fuel burns usefully and eventually turns into heat and the volume of working gases, and how much fuel does not burn and goes to the exhaust in the form of fuel vapor or products of its incomplete combustion. It is this unburned part of the fuel that is burned in modern "high-performance" cars in catalysts that are installed in the exhaust pipes. Those. exhaust due to the use of these systems is quite clean, but this system does not increase fuel efficiency and engine efficiency. On the contrary, it reduces - because in order to “pump” a portion of exhaust gases through a “dense grid” of catalytic surfaces, the engine has to work like a solid pump and spend a considerable part of its power on this matter. Of course, this category is somehow present in the formulas for calculating efficiency, but it is not explicitly and timidly present. For example, in such a form as, for example, in one of the formulas for the overall heat balance, there is a component “Q n.s. is the heat produced by incomplete combustion. But all these approaches suffer from a certain fuzziness, so I will try to state everything as clearly and as systematically as possible.

So, the overall efficiency of the engine will be decomposed into 3 main parts:

- fuel efficiency;

- thermal efficiency;

- mechanical efficiency;

The essence of these values is as follows:

Fuel efficiency- shows how much fuel was effectively burned in the engine and turned into a volume of working gases of high temperature and high pressure, and what part of the fuel was never burned and in the form of products of incomplete combustion, charred particles (in the form of smoke, soot and soot), or generally practically in the form of pure fuel vapor, passed the engine directly and flew out into the exhaust pipe. When you stand next to an old working domestic car, especially a truck, and you smell a strong smell of gasoline - this is exactly the result of such an inefficient type of partial combustion of fuels;

Thermal efficiency

- shows how much heat received from fuel combustion is converted into useful work, and how much is uselessly dissipated in the surrounding space;

Mechanical efficiency

- shows how much mechanical work is converted into torque on the main shaft and transferred to the consumer, and how much is uselessly spent on friction or spent on driving the supporting mechanisms;

Let's briefly consider all these positions:

Fuel efficiency

- on this topic, intelligible data could not be found either in the old Soviet textbooks on the theory and calculation of internal combustion engines, or in the endless resources of the modern Internet.

Intelligible and meaningful data were found in those data on the calculation of catalytic afterburners of unburned fuel for modern cars. After all, they also need to clearly calculate the performance of their afterburners for a certain amount of incoming unburned hydrocarbons in engines. So, from these data it follows that piston engines (diesels too) burn on average no more than 75% of fuel, but 25% of fuel vapors and products of its incomplete combustion go into the exhaust pipe and need the services of an afterburner (so as not to poison the environment ). Those. in the engines that exist today, no more than 75% of the fuel is fully burned and converted into heat. For 2-stroke engines, this value is even less.

Thermal efficiency- on average, piston engines have this efficiency in the amount of 35-40%. Those. about 65% of the generated heat is released into the environment without use through the cooling system and with the exhaust gases.

Mechanical efficiency - on average, 10% of the engine's work is spent on friction between its parts and on the drive of auxiliary engine mechanisms.

As a result, in terms of the sum of thermal and mechanical losses, modern piston engines of small sizes and capacities have an efficiency of no more than 30%.

In large engines, such as marine diesel engines or large engines of railway locomotives and trucks, energy savings are easier, but we will not talk about them.

But - the efficiency value of 30% does not take into account the proportion of unburned fuel, i.e. does not take into account the usefulness of the combustion of fuel vapors in the engine. I believe that, taking into account this parameter, the value of the real efficiency of piston gasoline engines will not exceed 20%, and diesel engines - a little more, by about 5-7%.

The result is better than coal-fired steam engines with their 7-8% efficiency, but still very little.

Let's think - why the specified "fuel efficiency" was not included in the concept of efficiency? Why does the concept of efficiency clearly ignore the share of fuel that does not "contribute" its part to the process of combustion and heat generation? Those. most of the losses of modern engines fall out of the concept of efficiency and the figures of modern efficiency values without taking into account these losses are clearly overestimated?

The truth lies in the very meaning of the term "efficiency". Those. it is a definition of the share of useful work - "actions", and the share of useless work. Some work or release of energy is beneficial, and some (for example, to overcome friction, or heat energy lost with exhaust) is useless, but it is there and this energy is tangible and taken into account. But the losses from unburned fuel do not appear either in the form of useless heat or non-target work. These “minuses of balance” are in no way loss of work or loss of heat. These are losses, fuel in its purest form. Those. these are losses neither in joules nor in atmospheres, but in grams and liters. And such losses cannot be measured or accounted for under the category of lost pressure or lost heat, useless action or wasted work.

Therefore, purely according to the rules of formal logic, the EFFICIENCY and should not take into account these losses. For this purpose, there should be a different indicator and determinant, but there is no such clear and distinct parameter in wide use. So we get a deliberately truncated and overly favorable indicator of the efficiency of modern engines - an efficiency indicator that takes into account only part of the losses ...

But in fact, the total efficiency of modern internal combustion engines turns out to be noticeably lower than the universally postulated efficiency of 35-40% efficiency. After all, only the useful action and the energy wasted in vain and the extra work produced by the burnt part of the fuel are taken into account. But the loss of the unburned part of the fuel from the total balance of the fuel supplied to the engine is not fully determined ...

REVISION AND INVENTORY OF LOSSES IN THE PISTON ICE We will try to briefly consider and analyze all the losses of energy contained in the fuel, one by one according to the positions outlined above. And then - to consider the possibilities of getting rid of these losses. Those. we will try to formulate the concept and outline the general features of a perfect engine.

* * *

* * *

First level of loss- incomplete combustion of fuel in the combustion chambers of the engine. All experts know that fuel in modern engines burns incompletely and part of it goes to exhaust with exhaust gases. That is why modern internal combustion engines poison the air with products of incomplete combustion of hydrocarbons, and in order to obtain a “clean exhaust”, a catalytic afterburner is installed in the exhaust pipe of modern cars, which “burns out” the fuel on the surfaces of its active elements. As a result, fuel that has not warmed up in the cylinders is uselessly oxidized in these catalysts. But the exhaust becomes cleaner. But the price of these catalysts with rhodium and platinum surfaces is very high and they work for a limited period.

A task- get an engine that COMPLETELY burns fuel in its combustion chambers and completely converts the energy of chemical bonds of fuel into heat and a large volume of simple combustion gases, such as water vapor and CO2.

First, let's look at why fuel does not burn completely in traditional piston engines. What hinders the implementation of the process of full combustion?

The main difficulty in piston engines on this topic is the lack of oxygen for combustion, as well as the implementation of the combustion process in one technological cycle with the expansion of combustion gases. The last situation can be described in other words - the Working Mixture does not have enough time for full combustion. These "birth diseases" of piston engines are practically incurable, so engineering thought, over more than 120 years of trying to get rid of them, has not found a way to do it.

Consider this disadvantage in detail: so when the piston is at Top Dead Center (TDC), the compressed Working Mixture (PCm) is ignited. The combustion process begins, which flows for some time. Approximate combustion of the working mixture in a modern high-speed motor lasts about a millisecond - 0.001 sec. In general, all 4 cycles occur in 0.02-0.04 seconds.

It is known that for the full and complete combustion of fuel vapors, high temperature and high pressure are desirable. But immediately after the piston passes TDC, it begins to move down with a significant increase in the volume of the over-piston space. Those. as the combustion front of the Working Mixture (PCm) propagates in the combustion chamber, the first portions of the burnt PCm will burn at high temperature and high pressure. But now the last portions of the burning PCm find themselves in conditions of sharply decreasing pressure and falling temperature. Accordingly, the usefulness of combustion drops sharply, or even stops altogether. For this reason, part of the PCM does not have time to burn out or burns incompletely. Therefore, part of the fuel vapor goes into the exhaust pipe and the exhaust gases certainly contain products of incomplete combustion of fuel hydrocarbons. The result is that part of the fuel does not burn and does not turn its energy into heat, and then into rotation of the main engine shaft, but only pollutes and poisons the surrounding air.

It is practically impossible to eliminate this drawback, since the fundamental design of a piston engine itself assumes the most important principle to be the connection in one technological cycle "combustion - expansion" of two different processes: combustion and expansion of combustion products. These processes are difficult to combine, since each of them proceeds optimally under conditions of mutually exclusive optimal conditions for the other process.

Indeed, the process of combustion of a compressed charge of PCm will best occur in a closed chamber of constant volume. In thermodynamics, this process is defined as an "isochoric" process. Those. the PCM charge will burn out completely and convert into heat and pressure all the energy of the chemical bonds of fuel hydrocarbons in a closed chamber under conditions of sharply increasing pressure and temperature.

And the expansion process will best occur at low temperatures (to provide lubrication of the sliding and rubbing surfaces of the working elements of the engine), with a slight movement of the main working body (piston).

As you can see, both of these conditions cannot be fully met in piston engines, so the combined process of “combustion-expansion” follows a “compromise scenario”, when little suitable conditions are created for each of the processes, but in the end, they still allow somehow implement the course of these joint processes at least by 50% efficiency. As a result, the process of operation of a modern piston engine is a technology of continuous difficult compromises and significant losses.

As a result of such a “compromise marriage union” with losses for both parties involved in the case, we get the following result:

— combustion occurs under conditions of a sharp expansion of the combustion chamber, and even at a significantly low temperature of the cylinder walls. As a result, the fuel burns incompletely and inefficiently, and even part of the heat from the burnt fuel is lost when the cold walls of the cooled cylinder are heated. Those. combustion takes place under extremely inefficient conditions.

— expansion occurs at high temperatures from the combustion process combined with the expansion. That is why the cylinder walls have to be cooled, because the oil for lubricating the rubbing surfaces of the piston and cylinder at a temperature of more than 220 ° C loses its “slippery properties” and friction begins “dry”, and the charred oil sinters into solid particles, which begin to interfere even more this process.

Partially, a way out of the impasse of the "burning - expansion" process is found by arranging "early ignition", so that as little as possible of the PCm combustion occurs on the line of high-speed expansion and high expansion of the volume of the combustion chamber. But this is a forced and fraught with other side troubles scheme. Since “pre-ignition” involves the ignition of the PCM and the creation of the initial stage of the working pressure of the combustion gases even before the piston reaches TDC, i.e. at the final stage of the "compression" cycle. Consequently, the inertia of the crank mechanism (KShM) has to overcome this emerging pressure of the burning PCM and compress due to the inertia of the KShM rotation or the work of other pistons, which began to expand the burning PCM. The result of this compromise is a sharp increase in loads on the crankshaft, pistons, connecting rods and crank pins, as well as a decrease in efficiency. Those. the engine turns out to be an arena of confrontation between multidirectional forces.

Another difficult topic in piston engines is the lack of oxygen. True, it is typical only for gasoline engines (engines operating with forced spark ignition), diesel engines (engines operating with compression ignition) do not have this drawback. But instead, diesel engines have acquired many other difficulties - a lot of weight, bulkiness and impressive dimensions. Indeed, no one managed to create an efficient diesel engine of acceptable dimensions with a volume of less than 1.2 liters ... This is the engine of the smallest diesel car Audi-A2. And leaving diesel engines in very small dimensions has a sad result. So - small diesel engines of the Vladimir Tractor Plant D-120 (they are placed on a mini-tractor) with a power of 25-30 hp. have a weight of 280-300 kg. Those. 10 kg of weight per horsepower. Other manufacturers around the world are in a similar situation.

So, the fuel does not burn out completely when the PCm is "rich", i.e. it has a lot of fuel vapors and little air (oxygen). Such a PCm has no chance to burn out completely, there is simply not enough oxygen to oxidize fuel hydrocarbons. The result is that the fuel vapors that have not burned out for this reason go to the exhaust. But on the other hand, such a PCm burns quickly, although defectively. This means that most of the fuel vapor still burns and gives the desired pressure and temperature.

You can go the other way - make a "poor mixture", i.e. there will be a lot of air (oxygen) in the PCM and little fuel vapor. As a result, in the ideal case, such a PCM will be able to burn out completely - all fuel vapors will burn out at 100% with full efficiency. But such a PCm has a big drawback - it burns much more slowly than a "rich mixture" and in the conditions of a really operating piston engine, where combustion takes place on the line of a high-speed increase in volume, such a PCm simply does not have time to fully burn out. Since a significant part of the combustion of such a PCm falls due to the low speed in the conditions of a sharp increase in the volume of the combustion chamber and a drop in temperature. The result - PCm again does not burn out completely even in the “poor mixture” option, and a noticeable part of it goes without burning out to the exhaust.

And again, the fuel efficiency of this mode of operation of the piston engine is very low.

The low supply of the PCm combustion process with oxygen is also played by the method of controlling carburetor engines - the “quantitative method”. In order to slow down the engine and reduce its “thrust”, the driver closes the throttle, thereby restricting air access to the carburetor. As a result, there is again a lack of air for burning fuel and again poor fuel efficiency ... Injection engines are partly devoid of such a drawback, but the rest of the troubles of a piston engine appear in them “in full”.

It is necessary to separate two extremely contradictory working technological processes - "combustion - the formation of working gases of high pressure and temperature" and "expansion of working gases of high pressure and temperature". Then both of these processes can begin to be carried out in specialized chambers and devices with the most optimal parameters. Those. combustion will occur "isochorically" - in a closed volume, with increasing pressure and increasing temperature. And the expansion can be carried out at low temperatures.

In principle, the idea to make such a "great division" was formulated by various inventors and engineers in various countries for a long time. For example, the development of the German company DIRO Konstruktions GmbH & Co. KG", on the topic of a piston engine with a separate combustion chamber. But so far no one has been able to offer a theoretically beautiful and technically workable scheme for implementation in metal. The same German company DIRO Konstruktions GmbH & Co. KG began obtaining patents for its developments about 15 years ago, but it has never heard of real success in creating a really working engine.

So, it is necessary to ensure a long process of combustion of the PCm charge in a locked volume - an "isochoric process". Under these conditions, it will be possible to burn a deliberately “lean mixture”, with a large excess air ratio, when the fuel vapors will burn completely, give the maximum possible amount of heat and combustion gases, and at the same time, minimally toxic combustion products will go to the exhaust. But this can be done only by providing a sufficiently long burning time for the "poor" PCM charge in a locked volume at increasing pressure and a significant temperature. Which is practically impossible to provide in a piston engine.

* * *

The second level of losses– significant losses of heat obtained from the combustion of “engine-assimilated fuel”.

The thermal balance of a gasoline engine is formed as follows:

1) - heat converted into useful work: 35%;

2) - heat lost with exhaust gases: 35%;

3) - heat lost from losses through the cooling system: 30%;

A task- get an engine with minimal heat loss to the external environment. Ideally, you can set a goal to create an engine with a thermal efficiency of 80%. But even if we manage to achieve this indicator of 65-70%, instead of 35% today, this will be a huge leap forward. Those. an engine of the same power with such efficiency will begin to consume 2 times less fuel than before.

Analysis of today's disadvantage: First, let's consider - why are there such large heat losses "on the side" in traditional piston engines? What leads to such a sad state of affairs?

The first category of heat losses- heat loss with removal through the walls of the cylinders with the cooling system. In general, to increase the thermal efficiency value, the engine should not be cooled at all. From this, the temperature of the engine parts will immediately rise - and this will char the oil (which creates a film for easy sliding on friction surfaces), and the piston will no longer move easily in the cylinder and the engine will soon jam. Here we again run into the contradictions of combining two processes in one cycle - combustion and expansion. The temperature during the flash of combustion in the initial period of ignition of the RSm reaches 3000 C°. And the maximum temperature of the oil, when it still lubricates and saves from friction, is 200 - 220 degrees. When this temperature threshold is exceeded, the oil begins to “burn” and char. To ensure high efficiency, it is not reasonable to cool the engine, but to ensure the possibility of movement of the main working body - the piston, lubrication is vital ... I.e. a cooling system that allows the piston to move in the cylinder dramatically reduces the thermal efficiency of the engine. This is a conscious and necessary reduction in efficiency.

The second category of heat losses– heat loss with exhaust gases. The temperature of the exhaust gases at the outlet of the cylinders for different sizes and engines ranges from 800 to 1100 ° C. Therefore, in an engine running at high speeds, the exhaust manifolds sometimes begin to heat up to a crimson glow ... This means only one thing - the fuel combustion energy, which has turned into the internal energy of combustion gases in the form of their high temperature, is lost irrevocably and completely useless. It is through this channel of "thermal losses" that modern internal combustion engines lose about 35% of the fuel combustion energy. And it is extremely difficult to turn this energy into useful work, the maximum that has been done is to insert a turbine into the exhaust tract, which turns the turbocharger compressor. This achieves an increase in air pressure entering the cylinders. And this slightly increases the efficiency. But - one must understand that the turbine "captures" not the elevated temperature, but the excess pressure of the gases leaving the cylinder. Those. this is a slightly different topic and economy of a different kind.

Thus, it turns out that the piston motor poorly “processes” not only the temperature, but also the high pressure of the working gases. In fact, working gases with an overpressure of 8-10 atmospheres go to the exhaust. This is a lot, one has only to remember that the first steam engines at the beginning of the 19th century had an operating pressure of 3 or 3.5 atmospheres and successfully worked in coal mines and metallurgical plants, like the engines of the first steam locomotives.

Here the whole point lies in the same geometric dimensions of the compression volume and the expansion volume. In a piston engine, they are equal, and nothing can be done about it. Ideally, these volumes should be different. A trick like the Atkinson cycle, when the compression volume in piston engines is less than the expansion volume, is ineffective, since the engine torque is sharply reduced.

But an increase in the volume of the expansion chamber will only make it possible to convert all excess overpressure into useful work, but the increased temperature of the hot gases of fuel combustion cannot be utilized by this method. The only thing that came to the mind of the engineers was to turn heat into work - to inject water into the cylinders. In theory: water, turning into high-pressure steam, will sharply increase the pressure of the resulting vapor-gas mixture and at the same time significantly lower its temperature. But, in a piston engine for more than 80 years of efforts in this direction, nothing effective and efficient has been created. The piston scheme of the internal combustion engine turned out to be very hostile to this idea and did not allow the steam cycle or vapor phase to be built into the engine cycle.

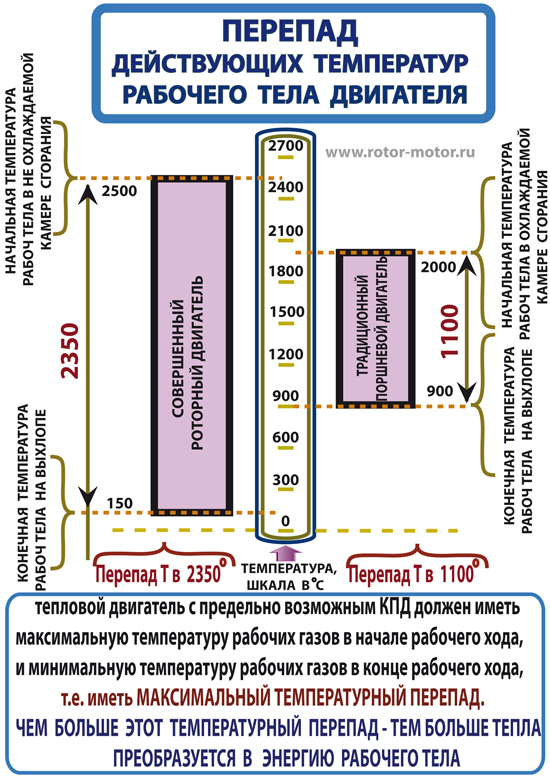

I must say that according to the fundamental law of thermodynamics, formulated almost 200 years ago by S. Carnot, a heat engine with the highest possible efficiency must have the maximum temperature of the working gases at the beginning of the working cycle, and the minimum temperature of the working gases at the end of the cycle.

But in a reciprocating internal combustion engine, the cooling system makes it difficult to obtain the highest gas temperature at the first stage of the cycle, and the impossibility of incorporating a steam component into the engine circuit prevents it from obtaining the minimum excess gas temperature at the end of the cycle. As a result, today we use engines with a thermal efficiency of about 35%, not much better than 60 or 70 years ago ...

The way to get rid of this shortcoming: it is necessary to create an engine design that allows the fuel combustion process to be carried out in a heat-insulated combustion chamber (to achieve the maximum temperature at the beginning of the working cycle), as well as to enable the vapor phase to be switched on at the final stage of operation of hot combustion gases (to achieve the minimum temperature at the end of the working cycle). Also, such an engine design will make it possible to do without a separate and bulky cooling system that would “throw out” heat into the external environment.

At the same time, the engine will not need a bulky and heavy exhaust pipe, which in traditional piston engines dampens the roar from exhaust gases emitted by “shots” with an excess pressure of 8-10 atmospheres. For in the proposed design, the excess pressure of the exhaust gases will be minimal.

* * *

The third level of loss- noticeable power losses to overcome friction forces, as well as inertia forces of reciprocating moving masses, as well as losses to drive auxiliary mechanisms. These losses are defined as mechanical losses. They depend on the kinematic scheme of the engine. But besides the actual mechanical losses, the kinematic scheme and its design also affect another important indicator of work, which is not directly related to the efficiency: this is the mode and magnitude of the torque.

The task is to obtain an engine with minimal mechanical losses. And also having a constantly acting torque of a high value with a small size of the engine itself. High and stable torque makes it possible to do without such a bulky and complex vehicle system as a gearbox. An example is transport with electric motors and steam engines.

Analysis of today's disadvantage: in a standard piston (trunk) engine, the reaction of the connecting rod (the transverse component of this reaction relative to the axis of the cylinder) to the pressure of the working gases constantly presses the piston to one side of the cylinder, then to the other. This system of engine operation requires constant lubrication of strongly rubbing surfaces, and the cost of overcoming these friction forces. In addition, when the crank crank rotates, the projection of the shoulder that creates the torque to the piston motion vector changes all the time from “zero” to “maximum” and back every working stroke. Such an all the time spasmodically pulsating torque mode is of little use for driving actuators. And only at high speeds of piston engines does the torque increase noticeably. But, high speeds (about 3-4 thousand rpm) are not needed by most consumers. Therefore, it is necessary to make a complex and bulky gearbox, which is an integral part of cars, motorcycles, etc.

In addition, the mechanical efficiency is noticeably reduced due to the power take-off of the engine to drive its auxiliary mechanisms - the cooling system pump, cooling fan, camshafts and gas distribution valves, an electric generator, etc. And noticeable power losses are also caused by the need to compress the working mixture, and the higher the compression ratio , the higher the losses. In addition, noticeable power losses can be caused by unnecessarily early ignition, when the engine is forced, at the end of the 2nd “compression” stroke, to compress the combustion products that begin to expand.

The way to get rid of this shortcoming: it is necessary to create an engine design in which the pressure of the working gases would not press the main moving working body to the stationary body. In this case, the engine should be distinguished by such a design that would allow to have a constant torque arm throughout the entire path of movement of the main working body of the engine. At the same time, on this path, the pressure of the working gases should be carried out for as long as possible, ideally - to strive for 100%. Let me remind you that in 4-stroke engines from a full engine cycle of 2 shaft revolutions, the pressure on the piston acts only half a turn, and even then in the mode of transferring this pressure with an unstable torque arm.

TOTAL:

SO - let's formulate the conditions that the scientific approach puts forward in order to create an engine with high efficiency:

1) The main technological processes of the engine "combustion" and "expansion" must be separated and spaced apart for implementation in different technological chambers. In this case, combustion should take place in a closed chamber, under conditions of increasing temperature and increasing pressure.

2) The combustion process must take place for a sufficient time and in conditions of excess air. This will allow 100% combustion of the working mixture.

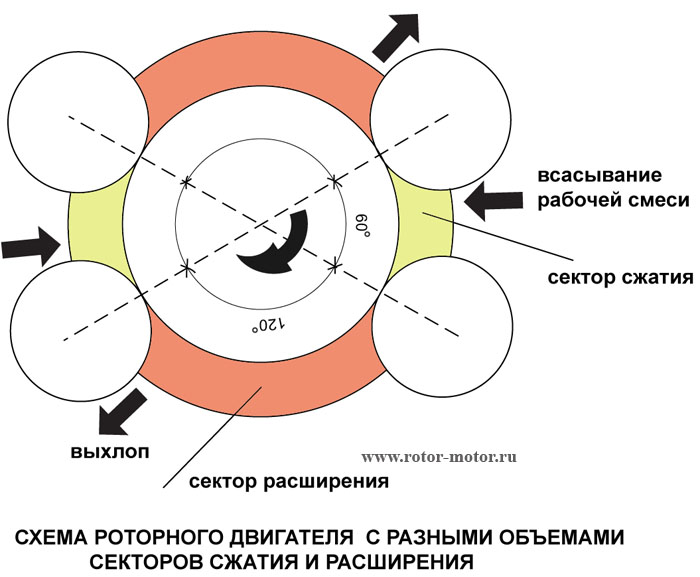

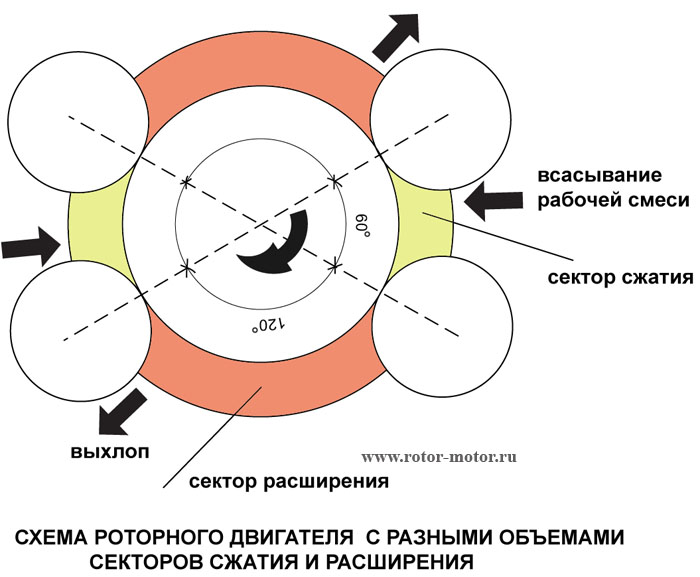

3) The volume of the expansion chamber must be significantly larger than the compression chamber, at least by 50%. This is necessary for the full transfer of the pressure of the working gases into work on the main working body.

4) A mechanism must be created to transfer the high temperature of the exhaust gases to work on the main working body. There is only one real possibility for this - the supply of water to convert the high temperature of the combustion gases into the pressure of the resulting steam.

5) The working body and all the kinematics of the engine must be arranged in such a way that the working body perceives the pressure of the working gases for as long as possible during the engine cycle, and the arm for transferring the force of this pressure is always the maximum possible.

After careful work with these requirements of the theoretical approaches of physics and mechanics on the topic of creating an engine with high efficiency, it turns out that it is absolutely impossible to create a piston engine for such tasks. The piston internal combustion engine does not satisfy any of these requirements. The following conclusion follows from this fact - it is necessary to look for more efficient, alternative to the piston scheme, engine designs. And the scheme of a rotary engine turns out to be the closest to the necessary requirements.

In my work on the concept of a perfect rotary engine, I just proceeded from an attempt to take into account, when creating a conceptual engine diagram, the need to implement all the above theoretical premises. I hope I managed to do it.

ARTICLE #2-1

THINKING ABOUT THE COMPRESSION RATE:

EVERYTHING IS GOOD IN MODERATION

We are all used to the fact that an economical and powerful engine must have a high compression ratio. Therefore, in sports cars, engines always have a high compression ratio, and engine tuning (forcing) to increase the power of standard mass-series engines primarily involves increasing their compression ratio.

Therefore, in a wide mass opinion, the idea was fixed - the higher the compression ratio of the engine, the better, since this leads to an increase in engine power and an increase in its efficiency. But - unfortunately, this provision is only partly true, or rather, it is true no more than 50%.

The history of technology tells us that when the first Lenoir ICE appeared in the 1860s (which worked without compression), it only barely surpassed steam engines in efficiency, and when (15 years later) the 4-stroke Otto ICE appeared, working with compression, then the efficiency of such a model immediately surpassed all engines that existed at that time in terms of efficiency.

But compression is not such a simple and unambiguous process. Moreover, it makes no sense to achieve very high compression ratios, and it is also very difficult technically.

First: the higher the compression ratio, the greater the stroke of the piston in the cylinder. Consequently, the linear speed of the piston at high speeds is greater. Consequently, the greater the inertial alternating loads acting on all elements of the crank mechanism. At the same time, the pressure levels in the cylinder also increase. Therefore, for an engine with a high compression ratio and a long stroke, all elements and parts of the motor must be of increased strength, i.e. thick and heavy. That is why diesels are not small and light. Therefore, small diesel engines have not been created for motorcycles, for outboard motors, light aircraft, etc. That is why, subjected to serious tuning - “pinched” standard auto engines have such a small motor resource.

Second: the higher the compression ratio, the greater the risk of detonation, with all the ensuing destructive consequences. Refueling with low quality gasoline can simply destroy such an engine. About detonation - read in a special ARTICLE. Those. at a certain degree of compression, more and more expensive and special gasoline or special additives to it have to be used. In the fifties and sixties, the main line of engine building, especially in the USA, was an increase in the compression ratio, which by the beginning of the seventies on American engines often reached 11-13: 1. However, this required an appropriate high octane gasoline, which in those years could only be obtained by adding poisonous tetraethyl lead. The introduction of environmental standards in the early seventies in most countries led to a halt in growth and even a decrease in the compression ratio on serial engines.

However, there is no point in reaching the maximum possible compression ratios. The fact is that the thermal efficiency of the engine increases with increasing compression ratio, but not linearly, but with a gradual deceleration. If with an increase in the compression ratio from 5 to 10 it increases 1.265 times, then from 10 to 20 - only 1.157 times. Those. after reaching a certain threshold of the degree of compression, its further increase does not make sense, because the gain will be minimal, and the growing difficulties will be enormous.

* * * By carefully analyzing the capabilities of different types of engines and looking for ways to improve their efficiency, you can find opportunities other than constantly increasing the compression ratio. And they will be far more efficient and superior than a high compression ratio increase.

To begin with, let's figure out what a high compression ratio actually gives. And she gives the following:

- gives a high stroke length, because in a piston engine, the length of the compression stroke is equal to the stroke of the expansion length;

- strong pressure in the charge of the working mixture, at which oxygen and fuel molecules approach each other. From this, the combustion process is prepared better and

goes faster.

The following comments can be made on the first position: indeed, the efficiency of diesel engines is largely due to the fact that they have a large stroke length. Those. increasing the length of the expansion stroke has a much more serious effect on improving the efficiency and economy of the engine than increasing the length of the compression stroke. This makes it possible to take more benefit from the pressure of the working gases - the gases work for a greater displacement of the piston. And if in “gasoline” engines the piston diameter is approximately equal to the stroke length, with the corresponding “compression ratio” and “expansion ratio”, which are tied to the piston stroke length, then in diesel engines this parameter is noticeably larger. In classic low-speed diesel engines, the piston stroke is 15-30% larger than the piston diameter. In marine diesel engines, this difference becomes generally blatant. For example, a huge 14-cylinder diesel engine for a supertanker manufactured by the Finnish company Wartsila, with a displacement of 25,480 liters and a power of 108,920 hp. at 102 rpm, the cylinder diameter is 960 mm, with a piston stroke of 2500 mm.

At the same time, let me remind you that such marine diesel engines run on crude oil, which can withstand a very high compression ratio with such a huge piston stroke.

But an increase in the compression ratio also has its unpleasant sides - it requires the use of expensive high-octane grades of gasoline, an increase in the weight of the engine, as well as a considerable amount of engine power for the process of strong compression.

Let's try to figure out if it will not be possible to achieve a close, and even greater effect in increasing power and increasing engine efficiency in other ways, i.e. without an excessive increase in the degree of compression with an increase in the inherent negative of such a process. It turns out that such a path is possible. Those. all of the positive aspects of increasing the compression ratio can be obtained in other ways and without the inherent troubles of increasing the compression ratio.

Consideration of the first position - long stroke length. The main thing for efficiency is a large stroke length so that all working gases transfer pressure to the piston to the maximum. And in a piston engine, the stroke is equal to the length of the compression stroke. This is how the opinion was somehow fixed that the most important thing is the degree of compression, and not the degree of expansion. Although in a piston engine these values are equal. Therefore, it does not make much sense to separate them.

But ideally, it is better to make these stroke lengths different. Since increasing the compression stroke leads to a lot of unpleasant consequences, then make it moderate. But the expansion course, as responsible to the maximum for economy and efficiency, should be made as large as possible. But in a piston engine it is almost impossible to do this (or it is very difficult and difficult to do it - an example is the Kushul engine). But there are a lot of rotary engine circuits that allow you to easily resolve this dilemma. Those. the ability of the engine to have a moderate compression ratio and at the same time a significant length of the stroke.

Second position consideration – activation and high efficiency of the fuel combustion process. Its high speed and completeness. This is an important condition for the quality and efficiency of the engine. But it turns out that the compression ratio (providing high pressure) is not the only, and not even the best way to achieve this result.

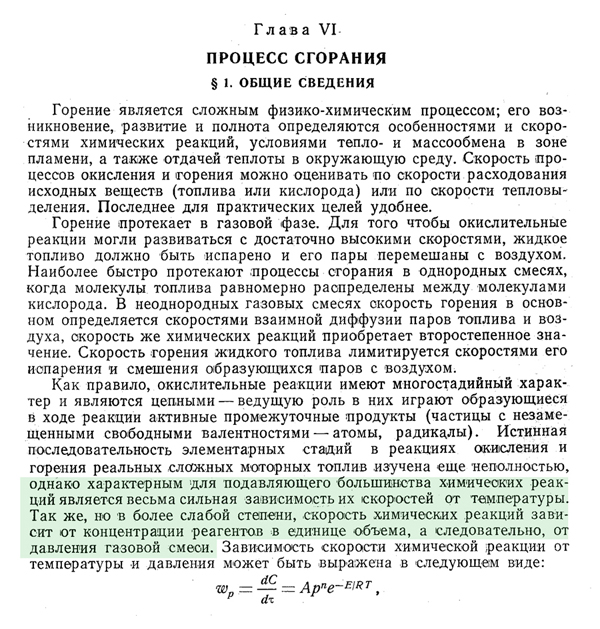

Here I will allow myself a quote from an academic book on the theory of engines for universities of the Soviet period: "Automobile Engines", ed. M.S. Khovakha. Moscow, "Engineering", 1967.

As can be seen from the quote above, the quality and speed of combustion depends more on the temperature of combustion, and to a lesser extent on pressure. Those. if it is possible to ensure the highest possible temperature of the combustion medium, then the usefulness of combustion will be maximum, and the need for an extremely high pressure before the combustion process (in the compression ratio) will disappear.

From all the theoretical approaches described above, one conclusion can be drawn - a powerful engine with high efficiency can do without a high compression ratio, with all the difficulties inherent in it. To do this, the expansion ratio in the engine must be noticeably higher than the compression ratio, and the combustion of the charge of the fresh working mixture must occur in an extremely heated combustion chamber. In this case, during the combustion process, the pressure and temperature should increase due to their natural increase due to the energy of the combustion process. Those. the combustion chamber must be hermetically sealed and not change its volume during the combustion process. Therefore: there should not be a rapid increase in the volume of the combustion chamber - with a corresponding drop in pressure and temperature (as happens in a piston engine).

By the way, during the combustion of the fuel mixture, the pressure in the closed combustion chamber of a constant volume will increase, i.e. the portions of fuel that burn in the “second series” (more than 60% of the mass of the charge) will burn at a very high compression ratio (pressure of about 100 atm.) the pressure of which will be created by the combustion of the first part of the fuel. Here it should be noted that the pressure of the completion of the compression stroke, even for diesel engines (these current champions in terms of efficiency) is no more than 45-50 atm.

But both of these above-mentioned conditions in a piston engine with a crank mechanism cannot be observed and ensured. Therefore, piston engines operate at high compression ratios, with all the ensuing difficulties, and have not been able to overcome the efficiency bar of 40% for almost 100 years.

THE SUMMARY OF THIS ARTICLE IS

– A high efficiency, high power, high efficiency engine can have a moderate compression ratio if it has an expansion stroke that is appreciably larger than the compression stroke. And the combustion of the working mixture will take place in a chamber locked for the duration of combustion and not cooled (isochoric adiabatic process) at increasing temperature and pressure from the energy of the combustion process itself.

Within the framework of the idea of a piston engine, it is impossible to create such a design, but in the field of ideas of rotary engines, it is quite possible to create such designs. What does the author of this text and this site.

ARTICLE #2-2

REFLECTION ON COMPRESSION RATE-2:

LOOKING INTO HISTORY

26.01.13

In the first part of the article, I showed that a continuous increase in the compression ratio in a piston engine with a crank mechanism - the only way to slightly increase the efficiency of the engine, has clear limits to its capabilities. At compression ratios approaching 16, the working mixture with even 100 octane gasoline vapor begins to burn out in detonation mode, and the engine parts and casing become very bulky and thick-walled (as in a diesel engine) in order to withstand high pressures and large inertial loads. But the huge forces of detonation combustion destroy even such bulky and massive parts very quickly.

But there are other ways to increase the efficiency of the engine - these are:

A) - increase the combustion temperature of the Working Mixture (temperature in the combustion chamber) in order to achieve complete and rapid combustion of gasoline vapors. In this case, the maximum amount of heat is released and the Working Body will press harder on the piston - i.e. do a great job.

Piston engines with a crank mechanism and a combined “burning-expansion” process (3rd stroke) cannot go along this path, since the oil (lubricating the walls of the “piston-cylinder” kinematic pair) at a temperature of 220 degrees already begins to char and stops lubricating. That is why the cylinder and piston of the engine must be cooled, and this leads to a sharp decrease in the thermal efficiency of the engine.

B) - increase in the volume (degree) of expansion of the Working Body (length of the expansion stroke) for the full expansion of the gases of the Working Body. This will allow full use of their excess pressure. In modern piston engines, gases with a pressure of 5-8 atmospheres go to the exhaust, which is a significant loss. And this despite the fact that the average effective pressure of a piston engine is only 10 atmospheres. The small length of the stroke of a piston engine with a crankshaft (crank mechanism) prevents an increase in the “actuation” of this pressure.

If you increase the degree of expansion of the gases of the Working Body in the engine, then its efficiency will increase significantly without the need to increase the compression ratio.

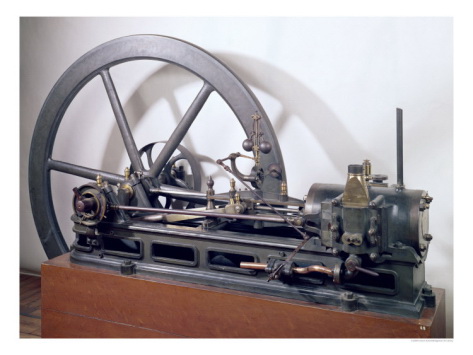

The first internal combustion engine in history was the Lenoir engine. 1860

So, the topic of this article: to increase the efficiency, it is possible and necessary to increase the degree of expansion of the Working Body (working gases) without increasing the compression ratio. This should lead to a significant increase in engine efficiency. Let's justify just such a possibility in this article.

At the optimum, you need to have: the compression ratio can be quite small - about 3 times, this corresponds to a pressure in the charge of the compressed Working Mixture of 4 atmospheres, but the expansion ratio (length of the stroke line) should exceed this small compression ratio by about 6-8 once.

Such a formulation of the question may seem strange and unreasonable to all connoisseurs of traditional engine schemes, who are accustomed to high compression ratios in piston engines. But just such a paradoxical state of affairs in reality is evidenced by a careful study of the designs of internal combustion engines that were created and operated at the dawn of the appearance of such engines, i.e. in the era of the creation of the first internal combustion engines.

So, the first misconception that works to reinforce the myth about the need to create a high compression ratio in the engine is justified by the fact that the first internal combustion engines, which were created 150 years ago, did not pre-compress the Working Mixture before it was ignited and therefore had a completely meager efficiency - almost the same as that of primitive steam engines.

Indeed, the first working internal combustion engine designed by Jean Lenoir (patented in 1859) had no precompression of the working mixture and operated with an efficiency of 4%. Only 4% is like the voracious and bulky steam engines of that time.

But the first example of a 4-stroke engine by Nikolaus Otto, created in 1877, worked with a pre-compression of the working mixture and showed an efficiency of 22 percent during operation, which for that time was a phenomenal achievement. At the same time, the degree of compression and the degree of expansion (like all current piston ICEs with KShM) were equal to each other.

Based on these data:

- Lenoir engine efficiency without compression - 4%;

- Otto engine efficiency with compression - 22%;

simple and clear conclusions are made - an engine operating with a pre-compression of the Working Mixture operates in a fundamentally more efficient mode, and - the higher the compression ratio, the better. This conclusion over the past 140 years has become a common truth, and for the last 100 years, engine building has been on the path of increasing the value of the compression ratio, which today has already reached its limit values.

BUT in the presentation of this information, there is one big BUT ...

It turns out that the same Nikolaus Otto, before creating his famous 4-stroke engine with compression in 1877, a little earlier - in 1864 he created, produced and successfully sold many hundreds of his other inventions - an atmospheric internal combustion engine operating without precompression. The efficiency of this engine was 15% ... Such a high efficiency does not fit into the theory that a strong pre-compression of the Working Mixture is absolutely necessary to achieve significant engine efficiency.

Something in this topic was not right, something was missing for understanding very important facts, and I decided to study this situation. And here are the conclusions I came to:

-absolutely terrible - scanty - the efficiency of the Lenoir engine was obtained because he had completely unacceptably small EXPANSION working gases;

- and the atmospheric Otto engine operating without compression had a very worthy efficiency of 15% from what it had very large EXPANSION working gases;

True, this Otto engine had very poor torque and a very uneven rotation of the main shaft, and therefore was quickly replaced by 4-stroke engines. But with the value of efficiency, he was very decent.

Let's take a close look at the dimensions of the working parts of the Lenoir engine and make some rough calculations. The piston diameter is 120 mm and the piston stroke is 100 mm. The descriptions of the engine of that time preserved the data that a distance of about half the length of the "expansion line" was allotted for the intake of gas and air. Then the supply valve was closed and the electric candle gave a spark. Those. the expansion process, or rather the combined “burning-expansion” process, had less than half the length of the working stroke ... A spark ignited a mixture of gas and air, a flash occurred, the temperature and pressure of the gases in the cylinder increased sharply and the working pressure drove the piston further with effort. The maximum peak of the working gas pressure on the piston was 5 atmospheres. But it must be understood that the Working Mixture was ignited under conditions of an ever-deepening pressure drop - after all, the piston continued to move creating a vacuum below atmospheric pressure ... Under such conditions, only a very “rich” mixture supersaturated with gas could be ignited. Accordingly, combustion in this mode was extremely incomplete, and even the combustion products could hardly expand fully - after all, the length of the working stroke was extremely small. Those. for a piston with a diameter of 120 mm. the stroke length was less than 50 mm. We can safely assume that gases of very high pressure went to the exhaust, and even supersaturated with unburned lighting gas. Accordingly, an engine of such parameters had a power of only 0.5 horsepower at a shaft speed of 120-140 rpm. So - we look at the Lenoir engine. This engine worked on a 2-stroke cycle. At first, on the line of the working stroke, the piston drew in the light gas and air (Working Mixture). The supply valve was then closed. The spark plug sparked and the Working Mixture ignited and the high pressure hot gas pushed the piston further. Then, during the reverse stroke, the piston pushed the combustion products out of the cylinder, and then everything was repeated again.

Those. in one working cycle - on the "extension line" - THREE work processes were combined:

- inlet of the working mixture;

- combustion of the working mixture;

– expansion of the Working Body;

OUTPUT- the Lenoir engine had such low efficiency and such low power, primarily due to the very short stroke length (when the working gases simply could not work) and the very inefficient organization of work processes, when the extremely “rich” Working Mixture was ignited at a pressure noticeably below atmospheric under conditions of active expansion. Those. this engine should have been designated as an engine operating with a PRE-EXPANSION (vacuum) of the Working Mixture ....

NEXT - consider the operation of another engine that worked without pre-compression of the Working Mixture, but had an efficiency of 15%. This is an 1864 Otto atmospheric engine. It was a very unusual engine. According to its kinematics, it seemed to be something completely ugly and unsuitable for work, but with a “clumsy” kinematic scheme, it acted according to a very rational scheme for organizing work processes and therefore had an efficiency of 15%.

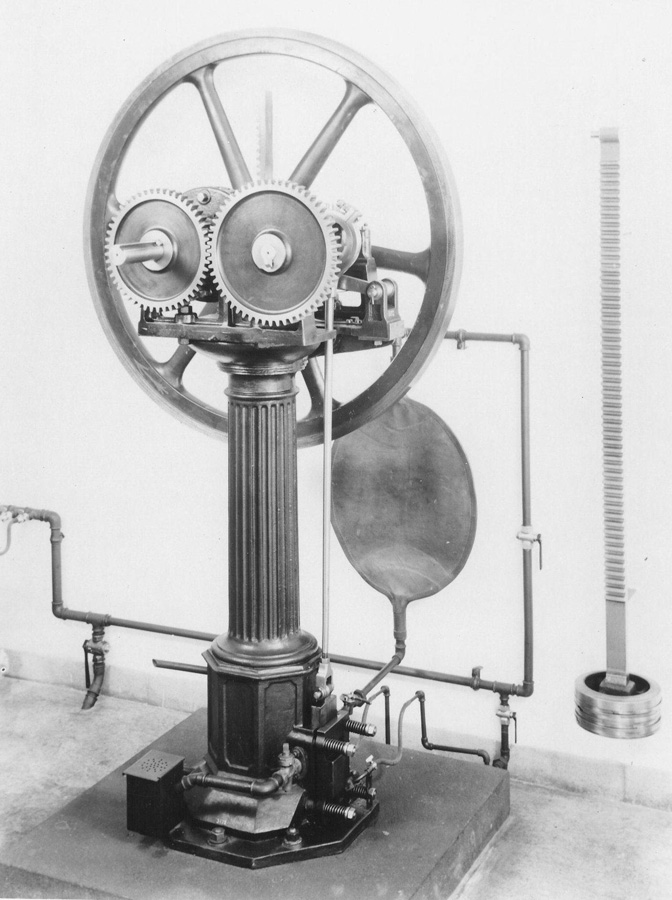

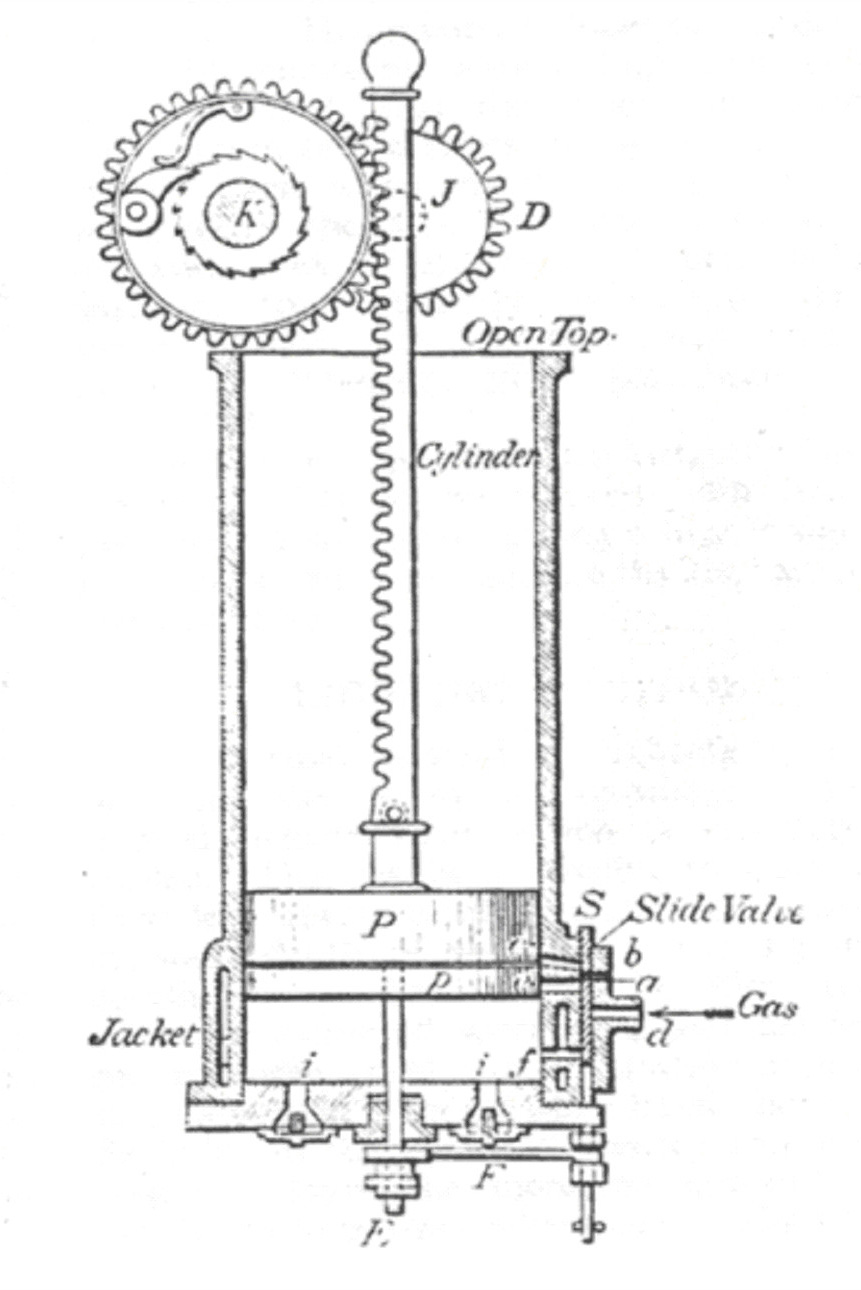

The cylinder of this engine was mounted vertically and the engine piston moved up and down. At the same time, this engine did not have a crankshaft, and the piston had a very long gear rack directed upwards, which engaged with the gear with its teeth and rotated it.

Atmospheric engine Otto model 1864. On the right in the photo is a piston with a long toothed rack, which gives an idea of the length of the stroke. At the same time, when the Working Mixture exploded under the piston, and the piston instantly flew up, the gear rotated idle, because a special mechanism disconnected it from the flywheel of the machine. Then, when the piston and rail reached the extreme top point, and the pressure of the working gases in the piston ceased to act, the piston and rail, under their own weight, began to go down. At this point, the gear was attached to the flywheel shaft, and the working stroke began. Thus, the engine acted with jerky impulses and had a very poor torque regime. The engine also had low power, since the force was created only by the weight of the piston and the rack (i.e., gravity worked), as well as atmospheric air pressure, when the cooling gases and the raised piston in the cylinder created a vacuum. That is why the engine was called atmospheric, because in it, together with the force of gravity, the force of atmospheric pressure also worked.

But on the other hand, in such a design of the engine, work processes were extremely well organized.

Consider how the work processes in this engine were organized and acted.

At first, a special mechanism raised the piston by 1/10 of the height of the cylinder, as a result of which a rarefied space formed under the piston and a mixture of air and gas was sucked into it. Then the piston stopped. Then the mixture was ignited with an open flame through a special tube. During the explosion of combustible gas, the pressure under the piston rose abruptly to 4 atm. This action threw the piston up, the volume of gas in the cylinder increased and the pressure below it fell, since the internal volume of the piston had no connection with the atmosphere and was hermetically sealed at that moment. When the piston was tossed by an explosion, a special mechanism disconnected the rail from the shaft. The piston, first under gas pressure, and then by inertia, rose until a significant vacuum was created under it. In this case, the working stroke turned out to be of maximum length, and continued until all the energy of the burnt fuel (in the form of an excess pressure of the Working Body) was completely spent on lifting the piston. Note that the photograph of the engine shows that the length of the stroke (cylinder height) is many times - 6-8 times the piston diameter. That's how long his working stroke was. While in modern piston engines, the piston diameter is approximately equal to the working stroke. Only in diesels - these modern champions of efficiency - the stroke is about 20-30 percent larger than the cylinder diameter. And here - more than 6 or even 8 times ....

Further, the piston rushed down and the working stroke of the piston began under the load of its own weight and under the influence of atmospheric pressure. After the pressure of the gas compressed in the cylinder on the way down to the piston reached atmospheric pressure, the exhaust valve opened, and the piston displaced the exhaust gases with its mass. All this time, a long rack and pinion turned a gear connected by a shaft to a flywheel. This is how the power of the engine was produced. After the piston returned to the lower point of the trajectory of movement, everything was repeated again - a special mechanism smoothly lifted it up and a fresh portion of the Working Mixture was sucked in.

There is one more feature - which played on a noticeable increase in efficiency. This feature was not in the Lenoir engine, nor is it in modern 2-stroke and 4-stroke engines. In such an unusual engine scheme, due to the maximum complete expansion of the heated Working Body, the efficiency of this engine was significantly higher than the efficiency of the Lenoir engine and therefore reached 15%. In addition, the ignition of the working mixture in the atmospheric Otto engine occurred at atmospheric pressure, while in the Lenoir engine this process occurred under conditions of increasing rarefaction, i.e. under conditions of an increasing drop in pressure forces, when the pressure turned out to be noticeably less than atmospheric pressure.

It is also necessary to say that, according to the principle scheme close to the scheme of this engine, today there are pile drivers - diesel hammers. True, the supply and ignition of fuel in them is arranged differently, but the general concept of the movement of the working body is the same.

In the Otto atmospheric engine, at the moment of ignition of the Working Mixture, the piston stood still, and during the combustion of the first portions of the fuel, an increasing pressure was created in the combustion volume, i.e. portions of fuel that burned in the second, third and subsequent turn - they burned out under conditions of increasing pressure, i.e. Compression of the Working Mixture occurred due to the increase in pressure from the flash and the release of heat from the first portions of the burning charge. At the same time, the inertia of the system pressing from above on the burning gas - a piston, a long rail and atmospheric pressure, created a strong resistance to the first impulse of upward movement, which led to a noticeable increase in pressure in the burning gas medium. Those. in the Otto atmospheric engine, the burning of the Working Mixture occurred under conditions of sharp compression of the main volume of the part of the combustible gas charge that did not yet begin to burn. Although there was no pre-compression by the piston. It was this actual compression of a significant amount of most of the fuel vapors (together with a long working stroke) that appeared during the combustion of the charge of the Working Mixture that played on the significant efficiency of the Otto atmospheric engine of the 1864 model.

But modern piston engines, like the Lenoir engine 150 years ago, are forced to set fire to a fresh charge of the Working Mixture under conditions of a sharply expanding volume, when the piston (and it is very powerfully driven by the connecting rod and crankshaft) desperately runs away from the bottom of the cylinder and expands the volume of the "combustion chamber" . For reference, the speed of the piston in modern engines is 10-20 meters per second, and the speed of the flame front in a highly compressed charge of fuel vapor is 20-35 meters per second. But in modern engines, to eliminate this unpleasant situation, you can try to set fire to the charge of the Working Mixture "early" - i.e. until the moving piston reaches the top dead center (TDC) end line of the previous stroke, or at a position near this point. But in the Lenoir engine, this was impossible, because after the piston reached TDC, the process of suction of a fresh portion of combustible gas and air began, and its ignition is possible only under conditions of a sharply increasing volume of the “combustion chamber” and a sharp drop in pressure in a fresh portion of the working mixture below atmospheric. That is why the Lenoir engine had such an extremely low efficiency.

It can be assumed that if the Otto atmospheric engine had spark electric ignition (like the earlier Lenoir engine), then its efficiency could well approach 20%. The fact is that when the charge of the Working Mixture in the cylinder was ignited with an open flame through a special tube during a flash, some part of the burning charge flew out into the atmosphere through this tube and these were noticeable losses ... If such losses could be eliminated, then the efficiency of this engine would certainly be higher .

But Otto did not have knowledge in the field of electrical engineering (like Lenoir), so he installed such a primitive and efficiency-reducing ignition system on his atmospheric engine.

CONCLUSIONS from this article are:

1)

- a well-established opinion about the possibility of achieving an extremely high engine efficiency mainly due to the maximum possible degree precompression Working Mix valid only for piston engine designs

, where the piston rapidly moving from the “bottom” of the cylinder towards the crankshaft (due to the forced drive from the crankshaft) expands the volume of the “combustion chamber” at a tremendous speed and reduces the pressure of the ignited (and also burning) charge of the Working Mixture. In the Lenoir piston engine, operating without precompression of the working mixture, this disadvantage of piston engines manifested itself especially clearly. Which led to its extremely low efficiency.

In modern piston engines of all types, in order to eliminate precisely this constructive “generic” drawback in the organization of work processes, an extremely high degree of precompression is used precisely in order to make a fresh charge of the Working Mixture burn at sufficiently high pressures and temperatures (despite the high-speed increase in the volume of the combustion chamber and the corresponding pressure drop in this chamber), which is the key to a relatively full-fledged combustion of the charge of the Working Mixture and the creation of a Working Body of high pressure and high temperature.

2)

- in the history of technology, there are designs of engines of other kinematic schemes and a different way of organizing work processes, where even without prior strong compression of a fresh charge of the Working Mixture, good efficiency values \u200b\u200bcan be achieved even with a very primitive design. An example is the Otto atmospheric engine of the 1864 model, with an efficiency of 15%.

3)

- it is possible to create a highly efficient internal combustion engine, in which the processes of combustion of a fresh charge of the Working Mixture and the creation of a Working Body of high parameters will occur by natural compression of the burning charge due to the forces of combustion under conditions of a combustion chamber of constant volume. Moreover, the process of pre-compression to high values (20-30 atmospheres), which is typical for modern piston engines, requires a significant amount of engine energy and the use of massive, bulky and heavy parts.

At the same time, the main contribution to achieving high efficiency will be made by a large parameter of the expansion volume (long stroke), which will be much larger than the compression volume.

EXACTLY THIS ENGINE, which does not require the costly and cumbersome Precompression of a high value fresh charge of the Working Mixture, the author of this article is currently creating. In this engine, pre-compression will be carried out to low values, and the main compression of the charge of the Working Mixture in the combustion chamber of a constant volume will occur due to the forces of the first stage of combustion itself. Ideally, it will be detonation combustion: flash - explosion. Further, the High Pressure Working Body will expand to the end of its capacity in the High Volume Expansion Sector.